The power source known as the lithium-ion battery drives modern society through its operation of smartphones along with laptops and electric vehicles and renewable energy storage systems. The global marketplace depends heavily on transporting these compact power storage units because of their increasing industrial adoption. The shipment of lithium-ion batteries presents special transportation difficulties because these batteries possess chemical properties that bring potential risks. The paper examines lithium-ion battery transportation by discussing existing rules and safety protocols together with packaging instructions and the lithium battery shipping regulations recent developments in the market.

Understanding Lithium-Ion Batteries and Their Risks

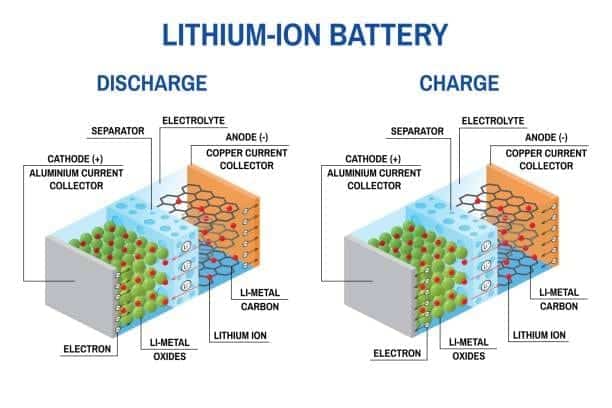

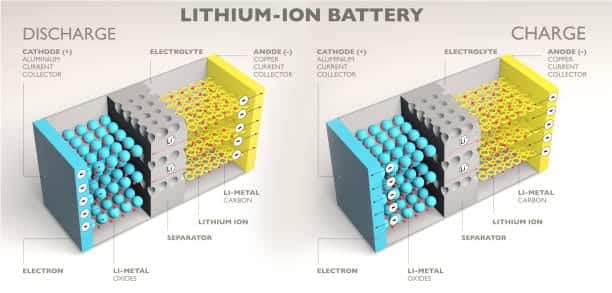

The chemical reaction between lithium compounds and electrodes alongside electrolyte serves as the power source in lithium-ion batteries to store then release energy. Their primary design features allow lithium ion batteries to remain lightweight yet efficient while also being rechargeable which led to their widespread consumer and industrial adoption. The characteristics which benefit lithium-ion batteries also harm them during transportation events. Lithium-ion batteries face a threat during extreme exposure since damage or short-circuits can lead to thermal runaway events which produce overheating until the batteries potentially ignite and explode.

The condition known as thermal runaway causes batteries to experience uncontrolled temperature elevation which sparks consecutive reactions leading to dangerous gas generation and high-temperature outputs. The shipping environment increases the danger for batteries because they encounter both mechanical pressure along with temperature changes and careless package treatment. Multiple incidents involving lithium-ion batteries have been recorded in passenger aircraft and on cargo vessels along with heavy vehicles which led authorities to establish stringent safety measures for these threats.

Global Regulations Governing Lithium-Ion Battery Shipping

The shipment of lithium-ion batteries demands adherence to numerous complex international and national transportation standards. Safeguarding procedures have been established by these regulations for all forms of transportation including aviation and maritime activities and surface transportation. Gunpowder shipping management falls under the oversight of multiple organizations including the International Air Transport Association (IATA) and International Maritime Organization (IMO) together with the United Nations (UN) and the U.S. Department of Transportation (DOT) and other country-specific agencies.

Air Transport: IATA Dangerous Goods Regulations

IATA Dangerous Goods Regulations (DGR) identifies lithium-ion batteries as UN3480 without attached equipment yet classifies them together with UN3481 when batteries accompany equipment. The specific class assignments determine the package requirements as well as labeling rules and state-of-charge restrictions. It is mandatory to limit standalone lithium-ion batteries for air transport to 30% state of charge to prevent thermal runaway incidents, which is one of the key shipping restrictions . Packages need to fulfill the requirements of the UN Manual of Tests and Criteria Part III Subsection 38.3 that examines battery performance under conditions of pressure and temperature extremes and vibration tests.

Sea Transport: IMDG Code

Fundamental regulations for shipping lithium-ion batteries by maritime routes come from the International Maritime Dangerous Goods (IMDG) Code. Batteries receive classification as Class 9 hazardous materials (miscellaneous dangerous substances) through the rules of the IMDG Code which follow the same principles as air transport regulations. Packages for shipment require official approval as well as warning symbols on the containers and complete hazardous materials documentation with a Dangerous Goods Declaration. Both higher state-of-charge (SoC) levels are feasible on sea shipping but the transportation of large consignments necessitates extra fire-blocking systems onboard vessels.

Ground Transport: National Guidelines

The worldwide standards for ground transportation follow the rules of the United Nations with slight country-specific modifications. Under U.S. regulations the Pipeline and Hazardous Materials Safety Administration (PHMSA) at DOT manages lithium-ion battery transport. All batteries need special packaging which avoids short circuits and displays correct labels together with Safety Data Sheets (SDS). ADR which functions under the Agreement Concerning the International Carriage of Dangerous Goods by Road (ADR) combines driver training with strict vehicles rules in Europe.

Packaging Standards for Safe Shipping

The base element for successful lithium-ion battery shipping safety consists of appropriate packaging procedures. For protection the batteries need proper shielding against physical stress factors along with protection against environmental conditions and short circuits. The UN Model Regulations supply a global framework for packaging that requires certain essential standards.

Inner Packaging

Operating cells or batteries apart maintains safety by keeping their terminals disjoined. Common protective materials that serve as non-conductors for lithium-ion battery packaging include plastic trays together with dividers and tape. Additional vermiculite or absorbent pads must accompany damaged or defective batteries since these protective measures serve to prevent leakage and fire events.

Outer Packaging

The outer shipping containers must meet robust requirements through fiberboard boxes, metal crates and plastic containers which follow UN performance standards. Drop and vibration tests join stack tests as mandatory quality assurance procedures for these shipping packages. Products with large battery packs including electric vehicles need special crate or pallet solutions for their transportation.

Labeling and Markings

Packages require display of three essential labels which include a lithium battery mark, Class 9 hazard symbol showing a diamond icon and battery symbol alongside the UN number and handling directions that state “Keep Away from Heat.” The markings on overpacks which contain multiple battery packages need extra labels to show their inner packaging compliance.

Challenges in Lithium-Ion Battery Shipping

Shipment of lithium-ion batteries continues to face ongoing obstacles in spite of strict governing regulations. The transportation of massive battery volumes daily produces excessive strain on logistics systems and makes current compliance guidelines increasingly difficult to follow.

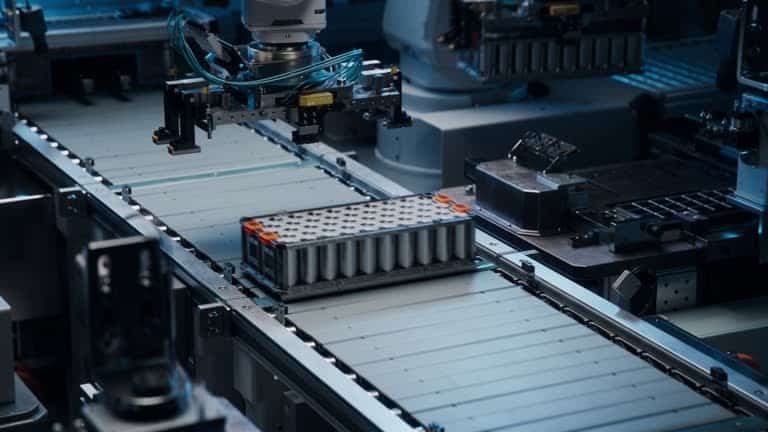

Volume and Demand

The increasing market demand for lithium-ion batteries stems from the electric vehicle and renewable energy sectors. The International Energy Agency (IEA) foresees battery demand escalating ten times until 2030. The fast-growing battery volume, especially from lithium ion cells, requires shipping organizations to increase their operations as they uphold safety guidelines but this expansion frequently produces port and airport congestion issues.

Counterfeit and Non-Compliant Batteries

Poorly made batteries or ones with incorrect labels create substantial safety hazards. The poor quality standards in these products lead to defective shipments that cannot pass SoC or packaging requirements which heightens the danger of product failures transporting lithium ion batteries. The interception of such shipments by enforcement agencies proves very challenging because many regions do not maintain proper oversight.

Damaged and Defective Batteries

Proper measures must be taken to ship defective batteries which also include recalled batteries. Fireproof protective containers need to be used for these units since they experience heightened thermal runaway potential. The analysis of their transportation or disposal practices creates additional costs together with complexity in supply chain operations.

Environmental Conditions

The environmental variables of high or low temperature alongside moisture and atmospheric pressure variation have the ability to make lithium-ion batteries unstable during shipping lithium batteries pose. The environmental conditions inside air cargo holds prove unstable for storage, particularly for batteries by air, and ships at sea create saltwater corrosion concerns for transported items.

Technological Advances in Battery Shipping Safety

The challenges from battery design and shipping practice innovations help resolve these problems. Product manufacturers along with logistics service providers unite their efforts to develop safer and more efficient operations.

Safer Battery Chemistry

The replacement of liquid electrolytes with solid materials in solid-state batteries leads to diminished fire dangers. The proposed technology remains under research but it might ultimately reduce regulatory complexity for battery shipments. Real-time battery management systems (BMS) add ability to monitor operational temperature and voltage levels so shipping companies can detect system malfunctions.

Smart Packaging

Packages with sensors react to heat intensity and monitor gas leaks as well as external destruction during transport handling. The implementation of these “smart” solutions allows businesses to take immediate proactive steps such as shipping reroutes and faulty package containment. The exploration of fire-resistant materials by companies includes ceramic-coated separators to contain incident situations.

Automation and Tracking

GPS-enabled tracking technologies together with automated storage systems optimize both battery shipping handling and the ability to track battery movements. The advanced technologies decrease human mistakes while generating vital routing data and storage optimization information.

Industry Case Studies and Lessons Learned

Lithium-ion battery shipping safety depends heavily on both industry standards and adequate preparation according to real-life shipping incidents.

2010 UPS Flight 6 Crash

A Boeing 747 aircraft crash occurred in near Dubai after failing to convey lithium-ion batteries which led to the demise of both pilots. The investigation linked the fire to faulty battery packaging which led IATA to strengthen their SoC and cargo hold fire protection regulations.

2019 Felicity Ace Fire

The luxury automobile cargo ship Felicity Ace sank after electric vehicle battery explosions lit the fire which consumed the entire shipment. The ship’s fire incident proved that dedicated firefighting tools are required when transporting large battery packages.

FedEx Ground Incidents

Lithium-ion battery shipments are identified as the cause behind multiple destructive fires that occurred at FedEx Ground distribution facilities. After these incidents organizations put in place better employee safety protocols and stronger rules regarding battery-containing consumer returns.

All these incidents emphasize the severity of minor errors in packaging procedures as well as handling and labeling practices which result in disaster throughout the supply chain.

Sustainability in Lithium-Ion Battery Shipping

Shipping operations face growing environmental assessment by industry regulators. The transportation of batteries creates carbon emissions mostly through the use of air freight since it produces greater environmental impact than water and ground-based options. The decarbonization of logistics operations includes routes analysis and electric delivery trucks adoption as well as the adoption of low-emission transportation methods.

The process of recycling together with reverse logistics operations has important functions. Solid recycling facilities benefit from proper transportation of end-of-life and used batteries which redeems valuable resources including lithium along with cobalt and nickel while minimizing waste. The battery recycling procedure needs special operating procedures for safely dealing with hazards from degraded materials.

Regulatory Bodies Governing Lithium Battery Shipments

The transport of lithium batteries requires diverse regulations according to the chosen shipping method which includes air transport, sea transport and land transportation. Two leading organizations UNECE and IATA together with the United Nations Economic Commission for Europe have created worldwide guidelines to manage shipments that stretch across various international borders during flight operations. The organizations create regulations that specify air transportation rules for lithium batteries through assigning unique UN codes for classification purposes.

The International Maritime Organization (IMO) operates through the International Maritime Dangerous Goods (IMDG) Code to regulate shipping of lithium batteries by maritime means.

Different nations have independent rules regarding land-based transportation of materials. When transport takes place in the United States the Department of Transportation through its DOT sets the standards which govern the shipment of lithium batteries. The European Commission (EC) serves as the authority responsible for deciding shipping standards throughout Europe. Shippers must adhere to particular shipping rules laid out by local and regional carriers on top of their mandatory regulations.

Hazardous Materials Classification

Lithium batteries belong to Hazard Class 9: Miscellaneous Hazardous Materials for international shipments conducted by ground and sea transportation. Some lithium battery shipments moved through cargo aircraft service can belong to this category when particular conditions apply lithium batteries by air.

The classification for lithium battery shipments through air transport depends on three main criteria: battery lithium content measurement and watt-hours rating and packaging methods.

- The amount of lithium metal within the battery

- The battery’s watt-hour (Wh) rating

- Packaging method

Categorization of Lithium batteries depends on both materials composition and packaging structure.

- The packaging criterion for loose batteries is they must not include equipment placement inside or around them.

- Batteries packed with equipment

- Batteries contained inside equipment

- Batteries in loose condition maintain 30% or lower state of charge (SoC)

The requirement for Class 9 labeling on lithium batteries depends on whether these batteries fulfill the two specified requirements.

- Studies show that Lithium Metal Batteries must have lithium content limited to less than 2 grams per battery and less than 1 gram per cell in case they are packed with equipment spare batteries.

- Packed equipment carrying Lithium-Ion Batteries must have cells up to 20Wh and batteries with a 100Wh maximum when inside the equipment.

Shipping Limitations for Lithium Batteries

The shipping limitations for batteries depend on the type of battery together with weight restrictions and number of cells included and proper packaging methods. The following limitations exist for battery transport depending on their category and delivery method.

Loose Lithium Metal Batteries

- Passenger Aircraft: Prohibited in cargo holds.

- The shipping of batteries through Cargo Aircraft requires the application of both Class 9 and Cargo Aircraft Only labels.

- Weight Limits:

- Packages containing cells with more than 1g lithium and batteries with 2g or more lithium must remain below 35 kilos per package yet admit unlimited number of packages.

- High-volume shipping allows packaging of unlimited small batteries up to 2.5kg each.

- The low-volume shipping method contains a maximum limit of 2.5kg per package for lithium cells weighing less than 0.3g lithium or a maximum of 2 batteries or 8 cells per package (one shipment contains only one package) ship lithium ion batteries.

Lithium Metal Batteries Packed with Equipment

- Passenger Aircraft: 5kg per package limit, regardless of lithium content.

- Batteries exceeding 2g lithium content as well as cells exceeding 1g lithium content may be shipped as cargo aircraft packages up to 35kg per package.

- Package Limits: Unlimited.

Lithium Metal Batteries Inside Equipment

- Passenger Aircraft: 5kg per package limit, regardless of lithium content.

- Cargo Aircraft: 35kg per package limit for batteries with >2g lithium or cells with >1g lithium.

- Package Limits: Unlimited.

Loose Lithium-Ion Batteries

- Passenger Aircraft: Prohibited.

- Cargo Aircraft: Requires Class 9 label and SoC of ≤30%.

- Weight Limits:

- Cells ≥20Wh or batteries ≥200Wh: 35kg per package.

- Each package containing cells or batteries under 20Wh with 200Wh limits may not exceed 10 kilograms.

- Each 2.7Wh or lower capacity lithium cell within a package can weigh up to 5kg in low-volume shipping arrangements unless packed together with a maximum of eight cells or two batteries (a single shipment contains only one package).

Lithium-Ion Batteries Packed with or Inside Equipment

- Cells ≥20Wh or batteries ≥200Wh:

- Passenger Aircraft: 5kg per package limit, requires Class 9 label.

- Cargo Aircraft: 35kg per package limit.

- Cells ≤20Wh or batteries ≤200Wh:

- Passenger and Cargo Aircraft: 5kg per package limit.

- Package Limits: Unlimited.

Complying international regulatory framework and national shipping standards can be achieved by shippers who follow these guidelines when transporting lithium batteries through multiple transportation systems.

Future Trends and Predictions

Investments in the future of lithium-ion battery shipping operations are likely to yield substantial changes. Regulatory bodies will strengthen rules when battery energy density elevates through requirements for either limited state of charge settings or sophisticated containment mechanisms. Through global cooperation countries should standardize regulations which will make it easier for international shippers to meet requirements lithium ion batteries contained.

The demand for economical shipping transportation will increase in African and Southeast Asian markets shipping batteries. The expanding market will affect existing infrastructure while generating growth opportunities for nearby logistics systems. Drone and autonomous vehicle technologies will handle small battery shipments through delivery but require development of safety standards.

Conclusion

Global lithium-ion battery transport operations require a careful procedure to fulfill worldwide market needs while controlling the multiple safety hazards. Through well-regulated standards together with technological advancements and multiple industries working together there has been steady progress bringing safety improvements but the problems of counterfeit products and environmental issues continue. The shipment sector must transform itself to continue following worldwide electrification shipping lithium batteries while protecting security and sustainability goals. Highly important results are achievable between adapting or failing to adapt since supply chain disruption and life danger accompany inadequate adaptation but successful adaptation produces a safer environmentally friendly future ship lithium batteries.